15kw 16bar screw air compressor

Today's laser cutters can efficiently process countless components including automotive, aerospace, healthcare, plastics, electrical and electronics, textiles, woodworking, and more with greater speed, precision, and quality. application.

The role of laser cutting machine air compressor

The clean and dry compressed air discharged from the special air compressor for laser cutting is partly supplied to the cutting head as cutting gas, partly supplied to the cylinder of the clamping table as a power source, and the last part is used to purge and dedust the optical path system.

How to select the suitable air compressor for laser cutting machine ?

1. There must be stable and sufficient gas to reduce the product of waste residue during cutting.

2. There should be corresponding high pressure, usually 10-16bar, larger laser cutting machine needs 20-30bar.

3. It is required to remove water and oil, and clean air can make the laser cutting machine work

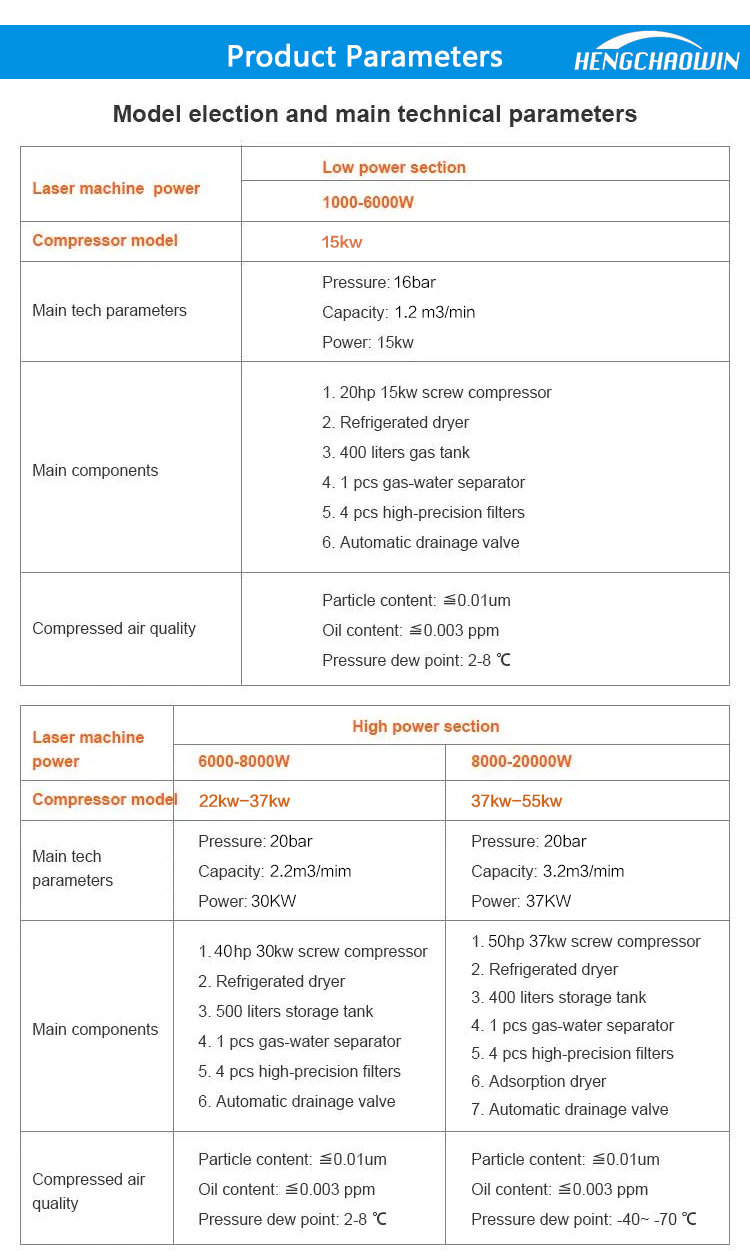

Parameters:

According to the needs of laser cutting machine, we recommend PM VSD screw air compressor, for more information, please consult Hengchaowin sales

|

Rotary screw air compressor for laser machine /

Compresor de aire de tornillo rotativo para máquina láser

|

|||||||||||||||||

|

Model

Modelo

|

HWV-7T | HWV-11T | HWV-15T | HWV-22T | HWV-37T | HWV-45T | HWV-55T | ||||||||||

|

air flow

flujo de aire

|

m3/min | 0.8 | 0.6 | 1.1 | 0.9 | 1.5 | 1.2 | 1 | 2.7 | 2 | 1.7 | 3.4 | 3.2 | 4 | 3 | 5.9 | 4.2 |

| cfm | 28 | 21 | 39 | 31 | 52 | 42 | 35 | 95 | 70 | 60 | 112 | 98 | 141.24 | 105.93 | 208.329 | 148.302 | |

|

working pressure

presión laboral

|

bar(kg) | 12.5 | 15.5 | 12.5 | 16 | 12.5 | 16 | 20 | 12.5 | 16 | 20 | 16 | 20 | 16 | 20 | 16 | 20 |

| psi | 174 | 217 | 174 | 217 | 174 | 217 | 290 | 174 | 217 | 290 | 217 | 290 | 217 | 290 | 217 | 290 | |

|

power

poder

|

KW / HP |

7.5kw/

10hp

|

11kw/

15hp

|

15kw/

20hp

|

22kw/

30hp

|

37kw/

50hp

|

45kw/

60hp

|

55kw/

75hp

|

|||||||||

| noise | db(A) | 62±2 | 66±2 | 66±2 | 68±2 | 72±2 | 78+2 | 78+2 | |||||||||

| Caliber | inch | RP 1/2 | RP 1/2 | RP 1/2 | RP 1/2 | RP1 1/2 | RP1 1/2 | RP1 1/2 | |||||||||

| Voltage/Frequency | 220v/380v/415v/440v/480v | More details please contact us | |||||||||||||||

|

Starting mode

Modo de inicio

|

variable frequency start | ||||||||||||||||

|

air dryer

secador

|

m³/min | 1.5 | 1.5 | 2.5 | 3.8 | 3.8 | 6.5 | 6.5 | |||||||||

|

line filter

filtro de línea

|

m³/min | 1.5 | 1.5 | 2.5 | 3.8 | 3.8 | 6.5 | 6.5 | |||||||||

|

air tank

tanque de aire

|

liter | 210 | 400 | 400 | 400 | 600 | 1000*2 | 1000*2 | |||||||||

|

Shape dimension

(mm)

|

L | 1700 | 1850 | 1850 | 1850 | 1450 | 1900 | ||||||||||

| W | 800 | 900 | 900 | 900 | 910 | 980 | |||||||||||

| H | 1650 | 1650 | 1680 | 1680 | 1290 | 1970 | |||||||||||

| Weight | KG | 450 | 520 | 520 | 600 | 720 | 1100 | ||||||||||

Standard of special air compressor for laser cutting:

1. Oil content in gas production: ≤0.001ppm

2. Water content in gas production: pressure dew point≤5℃

3. Gas containing particles: ≤ 0.01u

The above are the requirements of ordinary laser cutting machines. If you are a laser machine with more than 10,000 watts, the requirements are higher as follows:

1. Oil content in gas production: 0

2. Water content in gas production: pressure dew point -40℃

3. Gas containing particles: ≤ 0.01u

For more technical questions, please feel free to consult us~